Company profile

We love cars…

…not least because many of them have a piece of VOIT inside!

Since 1947, the technological company VOIT has stood for innovative products and manufacturing processes and, since that time, it has been growing together with its customers, the major automotive manufacturers and their suppliers. What started out as a small family company in the Saarland, Germany, is now one of the 12 largest companies in that region. As a multinational systems supplier for the automotive industry, the corporate group employs a workforce of approximately 1,000 employees at the company headquarters in St Ingbert and around 2,000 employees in 5 production locations in 3 countries worldwide.

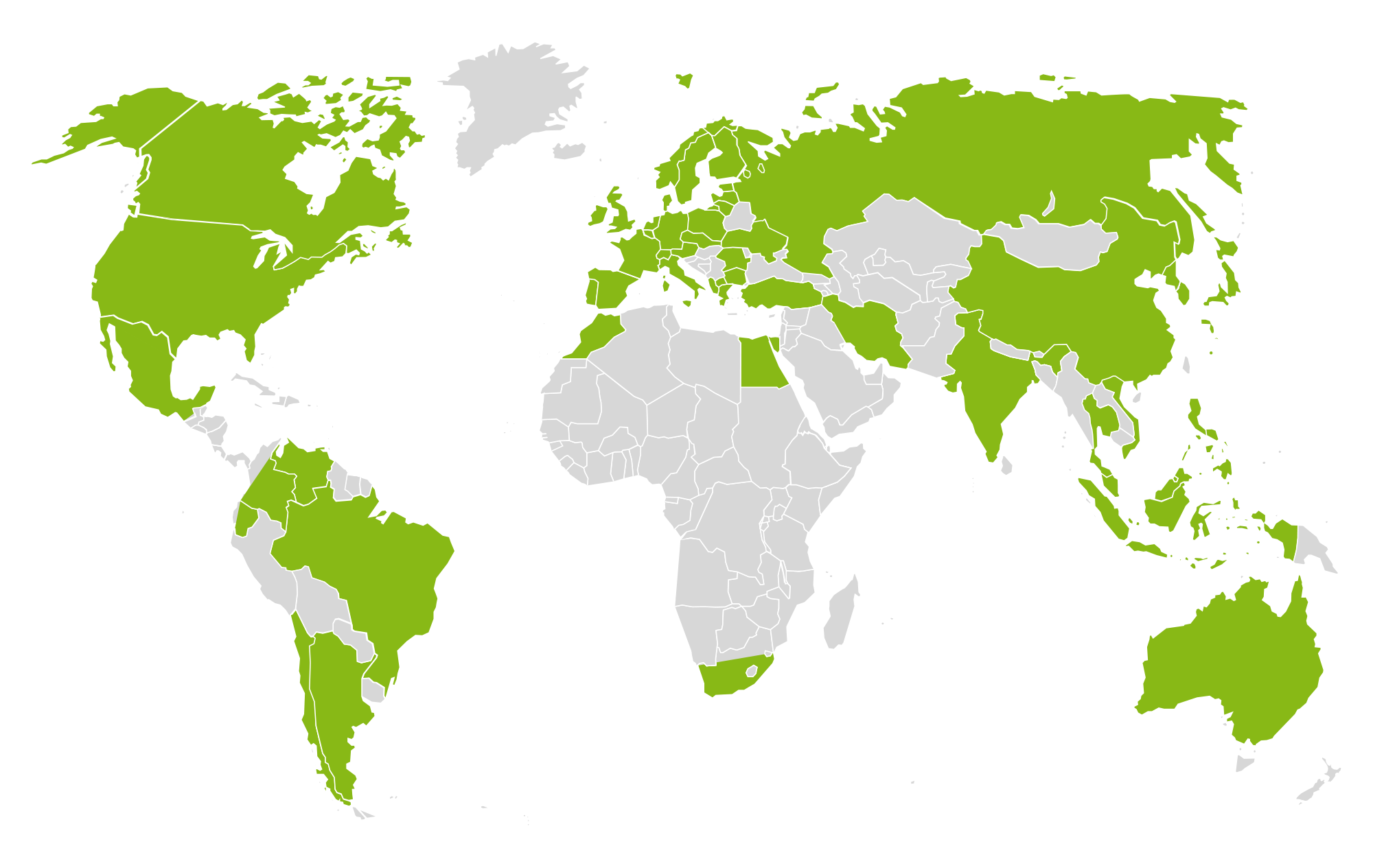

Over 100 million of our parts are installed annually at Audi, BMW, Mercedes, VW, Ford, Chrysler, Jaguar and Land Rover in functional areas such as the engine, fuel supply, powertrain, exhaust system, chassis, body and assistance systems. Around 65% of leading global manufacturers place their confidence in VOIT. Thanks to our customers, the largest OEMs and tier-1 suppliers, our products are to be found in the most beautiful and innovative vehicles in the world: in over 45 makes and around 250 vehicle models. We are thus making a decisive contribution to the mobility of the future, as a manufacturer and as an engineering partner.

Our product is “the process” – forming technology and aluminium pressure die casting are our passion!

VOIT stands for innovative product engineering as well as process and production excellence. Our employees in our competence centers for forming technology, pressure die casting, machining and our own in-house competence center for toolmaking have a high level of material and process expertise as well as a love of detail.

We master and develop the whole process chain from engineering through manufacturing, machining, assembly and joining operations right up to the ready-to-install series component and just in time delivery. Therefore highly precise customized aluminium pressure die cast components with completely machined functional surfaces are produced as well as finished castings and modules and components using forming technology, stamping, drawing and roll-bending technology. It is this combination of cross-disciplinary material and process expertise as well and innovative manufacturing technology which makes VOIT so unique.

We master complexity and precision

Our processes are just as sophisticated as your products and your increasing demands. Together with our customers, we develop ourselves further both technologically and ecologically… from complex components to increasingly ready-to-install assembly groups … and from early product engineering through prototyping up to ready-to-install series components produced in large scale manufacture.

Creating synergies

Our core competence lies in finalizing our customers’ complex product drafts and enabling them to be produced on a large scale in a reliable process. In a time when life cycles are becoming ever shorter, we enter the mutual product development process with our customers as an engineering partner as early as the development phase including prototype development in order to reduce the time to market and to find the most economical method of implementation. We go into the development phase with an open mind for technology. For each product design draft, there are uncountable possibilities for realization: various materials, various manufacturing technologies, various processing options. Finding THE version of a product out of all of these product and process possibilities which can be implemented economically, with a high degree of precision and a reliable process – that is our core competence and your benefit in working with VOIT.

Mobility of tomorrow – VOIT “electrifies“

Electromobility and autonomous driving are the great automotive trends of the future and act as stimulation for drivers, OEMs and suppliers to the same degree. Even today, VOIT is moving in the tomorrow’s world of electrification. Powertrain components for vehicles with combustion engines are being developed and manufactured as well as for hybrid drives and purely electric drives. Internal transmission components such as disk carriers, axial pistons, planetary carriers and intermediate plates right up to control units and complete housing components for E-axes are just a few of our products. The product fields of driver assistance systems also play an increasing role in the future of autonomous driving and electrification. Here, we develop and produce, among other things, components for braking systems, thermal management, chassis and air suspension as well as products for electric power steering. At the cutting edge, we create highly complex, innovative manufacturing technologies which are then applied in series production such as friction stir welding in series thus allowing interesting new design possibilities for the future in cooling engines, power electronics and aggregates of E-mobility. Just submit an inquiry to us!

Since we love cars and are moving forward. In future too.

VOIT – emotion for mobile worlds