Research & Development

Initiated by market analyses, benchmarking and intensive discussions, we are continuously searching for optimized solutions for our clients’ requirements. This is often carried out in cooperation with our clients or partners in industry and research.

The requirements of the functionality of technical components are constantly increasing and therefore the degree of complexity is also increasing further. It is the aim of the VOIT development department to implement the necessary complexity and to eliminate any unnecessary complexity.

With this development approach, we are able, time and time again, to implement stable processes for our customer applications. The customer therefore receives a manufacturing process which has been optimized with regard to the process in accordance with the component design presented. The component design and manufacturing process are also evaluated concerning the use of material and, at every stage, lightweight construction trends in the automotive industry are taken into account.

Objectives

Focus on the essentials

Reduce complexity

Increase component functionality

Harmonize component design and manufacturing process optimally for production

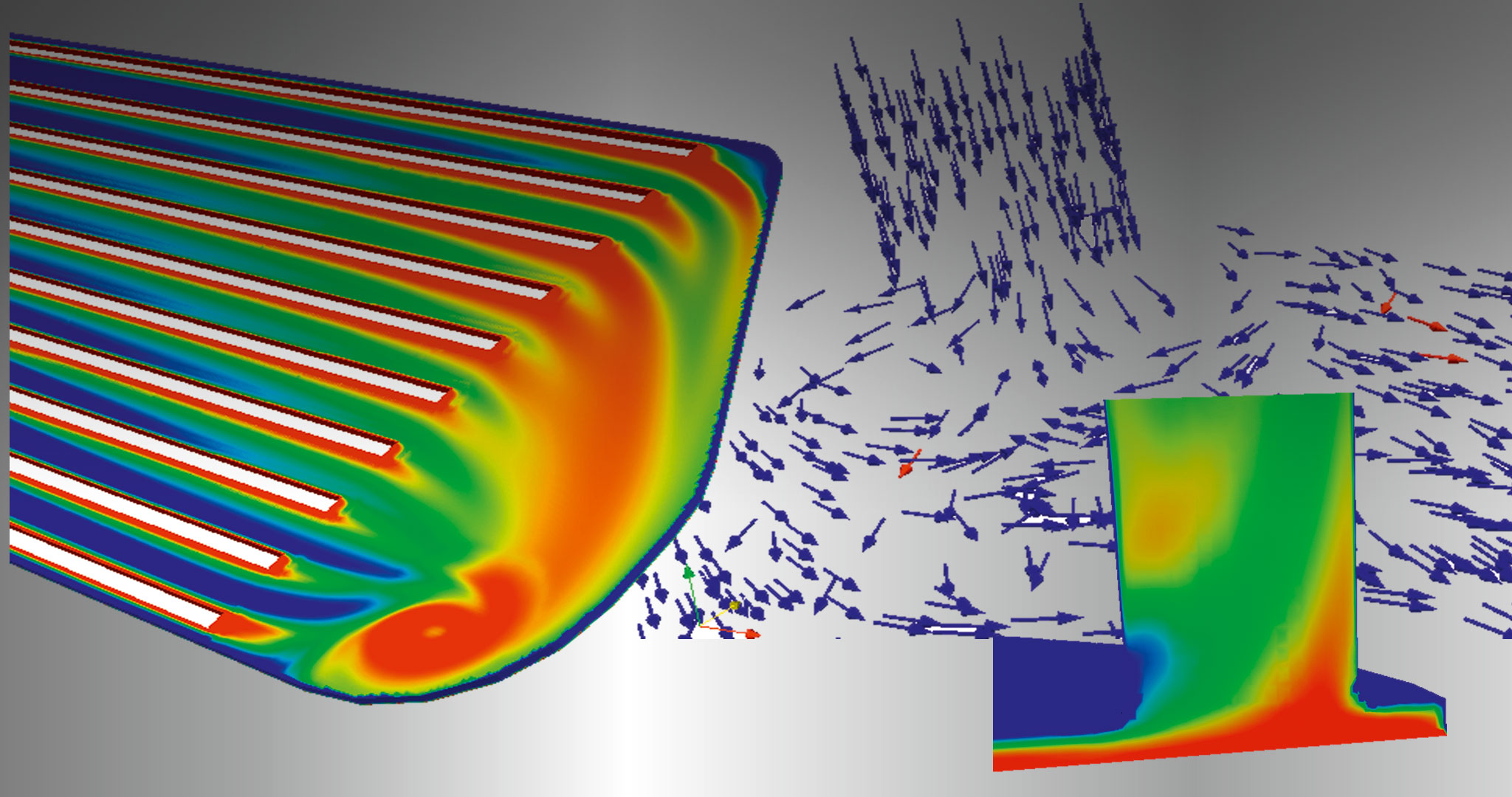

In developing the process, we use the latest development methods. Besides finite element calculation for the component, simulations of deformation and solidification as well as process simulations are carried out. A modern CAD-System (Siemens NX) combined with finite element calculations and numerical process simulation tools are used as a matter of course.

The simulation results are evaluated in our laboratory. These include, specifically, material and hardness analyses, metallographic examinations and surface analyses on component cleanness and adhesion of glue/paint.