-

eMotion for mobile worlds

With new OEM customers and technologies, VOIT increasingly taps into new, future-orientated components for modern transmissions and driver assistance systems for e-mobility and autonomous driving.

2018

-

VOIT celebrates its 70th birthday and receives the Q1 Award

With around 2,000 employees at five production locations, VOIT is proud to receive a special award in the company's 70th year: presentation by Ford of the golden crown of the Q1 Award.

2017

-

New location in France: the Fonderie Lorraine

A new member in the VOIT corporate group since 01.01.2017 is the French Fonderie Lorraine S.A.S - a joint venture between ZF Friedrichshafen AG and VOIT Automotive GmbH with the majority of shares and technological leadership being held by VOIT Automotive.

2017

-

VOIT becomes VOIT Automotive - VOIT opens a large press center and becomes a 1st tier supplier

The previous companies WILLY VOIT GmbH & Co. KG, VOIT HOLDING GmbH & Co. KG and VOIT Geschäftsführungsgesellschaft mbH merge to become the new VOIT Automotive GmbH.

In May, VOIT opens its large press center in Plant 1. The heart of the center: AIDA1, which is already supplemented as early as the 1st quarter of 2016 by AIDA2. With this technological leap forward and acquisition of further OEMs, VOIT manages to make the transition from 2nd tier to 1st tier supplier.

31.12.2014 / 1. Jan. 2015

-

VOIT becomes “North American Supplier of the Year” in the category “Direct Material Supplier”

VOIT takes another close look at its lean processes and sets new standards.

VOIT Automotive de MÉXICO is presented with the award “North American Supplier of the Year” in the category “Direct Material Supplier” by ZF Friedrichshafen AG. It is the result of untiring further development and dedication to the highest standards of excellence.

2014

-

CSR – Corporate Social Responsibility

Corporate Social Responsibility: In cooperation with the Bertelsmann Foundation and within the context of a programme of excellence, a new CSR concept is developed whereby the topics of energy, HR and innovation are given a more sustainable and future-orientated alignment. The certificate awarded is orientated around the CSR and sustainability standards of the Global Reporting Initiative (GRI) of ISO 26000 and the UN Global Compact.

2014

-

VOIT refines its portfolio

VOIT starts its new strategy of “future fields” which has a stronger focus on the megatrends of the future and customer's wishes such as sustainable mobility, driver assistance and safety concepts as well as connectivity and infotainment. The strategy entails concentrating on the fields of efficiency, lightweight design, powertrain and comfort and safety.

2013

-

Resources and energy efficiency

VOIT sets up a comprehensive energy management system and is certified for the first time according to DIN EN ISO 50001. This represents an enormous impulse regarding energy efficiency of production and reduction in CO2 emissions and is therefore a contribution in the sense of corporate responsibility.

2013

-

BIEG Invest becomes the new parent company

From a family company to a technological company with a family tradition:

BIEG Invest acquires majority ownership of the VOIT Holding and is now the group's parent company.2013

-

65 years of VOIT: On the path to growth

VOIT receives the award "Preferred Supplier of the Bosch Group in the material group Stamped, Drawn and Bent Parts".

The aluminium die casting division is enlarged by over 30% in order to meet rising demand for transmission components for the popular 8HP automatic transmission from ZF. With approximately 1.5 million intermediate plates, 2 million cups and 4.4 million piston rings, respectively, each year, VOIT has been a key supplier to ZF for years now.

VOIT TPH GmbH Technology for Press Hardening is launched:

With the new technology for hot forming, large scale production of high-strength lightweight components begins in autumn 2012. This process and engineering competence, also regarding product development with an open mind for technology, is to pay off in subsequent years.2012

-

VOIT has grown by 400% since the 90s

VOIT components are fitted in 60-65% of vehicles worldwide.

Topics this year: Lean management, development of a new corporate identity, adjustment of the product portfolio

2011

-

Year 1 after the crisis

Already in the first year after the crisis, break-even point has been reached again. VOIT invests 20 million euros in the St. Ingbert site, e.g. for production of the new energy-saving 8 HP transmission components for ZF. These components trigger a boom in the industry and are fitted by BMW, Audi, Jaguar, Landrover and later also by Chrysler.

Due to its technological expertise in the production of significant components such as intermediate plates, pistons and cups, VOIT has qualified as sole supplier. With further strategic products in automotive future fields such as electric steering, which is installed at Daimler and BMW, VOIT has also positioned itself for the future.

2010

-

Economic crisis successfully overcome – Entrance of BIEG Invest Engineering & Beteiligungsgesellschaft

The economic crisis in the automotive industry hits the whole group and leads to a drop in revenues of up to 50%. Through partnership, transparency, organisational talent and family spirit, the economic crisis is successfully overcome. BIEG Invest Engineering & Beteiligungsgesellschaft enters the VOIT Holding (parent company of the group at that time)

2009

-

Foundation of BTI Bearbeitungstechnologie St. Ingbert GmbH with investment by BIEG Invest

2008

Juni

-

Management of change commences

VOIT restructures itself, adjusts the product portfolio and positions itself clearly on the international market.

2008

-

New logistics center goes into operation.

2005

-

Foundation of VOIT-TEC

Milestone: Foundation of VOIT-TEC as the first large press center. It manufactures formed parts for automatic transmissions in material thicknesses of up to 8mm.

2004

-

Quality Award: Supplier of the year (Siemens)

VOIT implements environmental management according to DIN ISO 14001.

2000

-

Foundation of VOIT MÉXICO

Foundation of VOIT MÉXICO, then still known as Grupo KERVO, in Mexico.

VOIT receives the Bosch award for "Quality and Special Performance" for the seventh time and is therefore among the "Top Twelve Suppliers".

1999

-

Foundation of VOIT HOLDING and VOIT FRANCE

VOIT HOLDING GmbH & Co. KG (St. Ingbert) and VOIT FRANCE SNC (Henriville) are founded. The company meanwhile has a workforce of 650 employees in St. Ingbert.

1998

-

VOIT becomes market leader

In its 50th anniversary year, VOIT achieves a turnover of over 100M Deutschmarks.

Around twelve million stamped components are manufactured monthly of which 5-8 million are windscreen wiper components. In this field, VOIT is market leader. In addition, up to a million motor housings for electric drives for wipers, electric windows and car seats are manufactured.1997

-

Start of production of transmission components for ZF

Start of the transfer line. Diesel injection pump housings in pressure-tight aluminium die casting are processed on a transfer line with 300 CNC axes.

Start of production of transmission components for ZF.

1995

-

The company becomes increasingly successful worldwide and Willy Voit receives the Order of Merit of the Federal Republic of Germany

Willy Voit, who, with great humanity, untiring commitment and entrepreneurial talent, made a magnificent contribution to building the company and shaping its destiny, dies. Several months before he passed away, he was awarded the Order of Merit of the Federal Republic of Germany for his achievements as a businessman who made a decisive contribution to improving the economic structure of the Saarland.

The company becomes increasingly successful on a global scale. The countries supplied meanwhile also include Belgium, France, Japan, Korea, Mexico, Slovakia, Spain, South Africa, the Czech Republic and the USA. In 1990, the company achieves an export quota of over 30%. Around 600 employees manufacture around 12 million stamped and cast parts a month.

1990

-

VOIT receives the BOSCH Quality Award for the first time

1985

-

First cold chamber die casting machine.

With the installation of a cold chamber die casting machine, the age of casting technology finally begins. Initially, the technology used is zinc die casting but soon it is succeeded by aluminium die casting.

1981

-

VOIT patent

Drawn parts are replaced by rolled housings with a convoluted lid.

1977

-

The first fully automatic plastic coating system in Germany goes into operation

Housings for ventilator motors are produced using rolling technology.

1968

-

First wiper motor housings using Traktrix drawing technique

1965

-

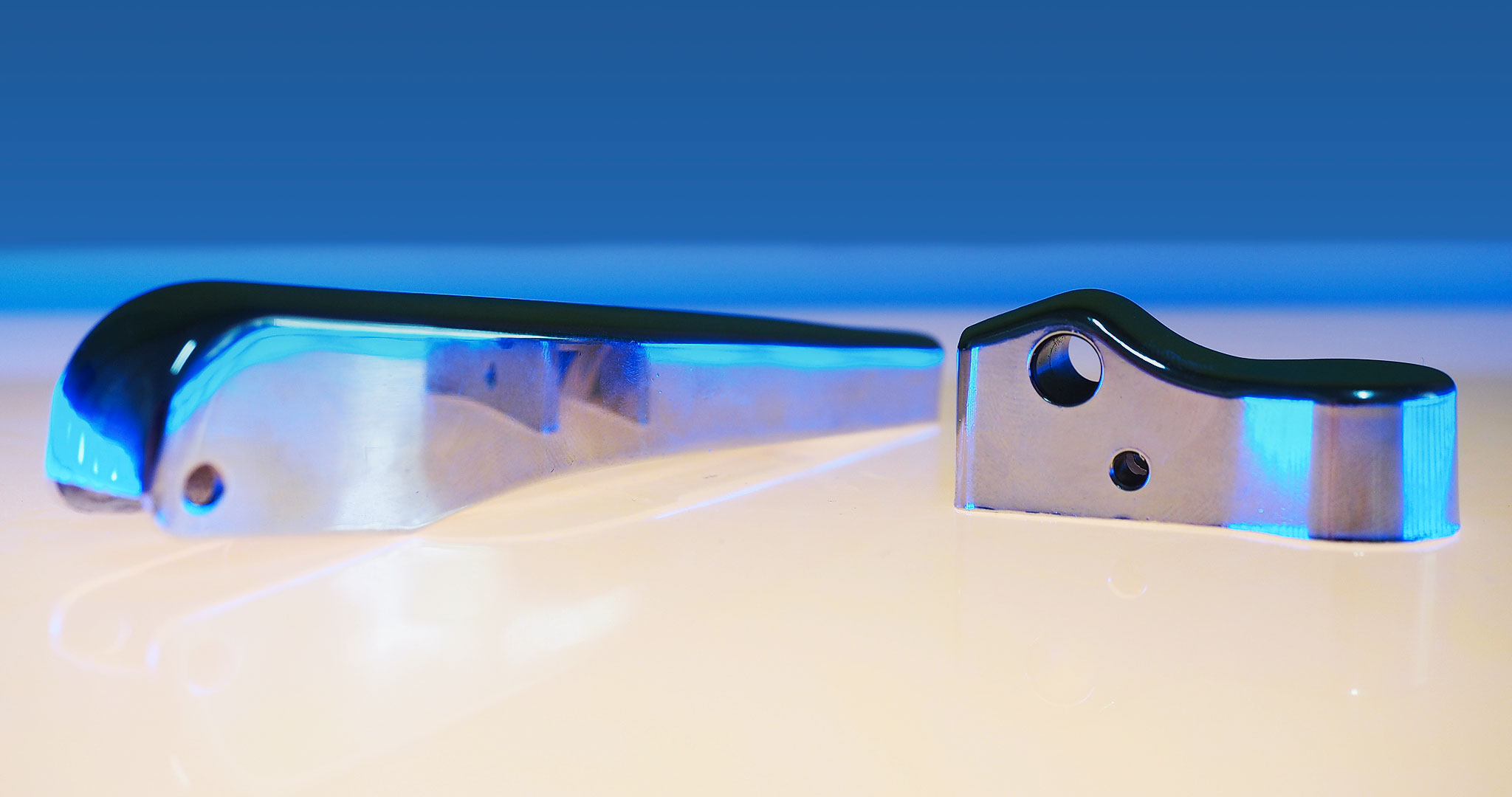

Voit becomes an automotive supplier with the "elephant tooth"

With the production of chrome-plated joint supports for wiper systems for Bosch, VOIT gets off to a flying start as an automotive supplier. These products, also popularly known internally as the "elephant tooth", are installed in huge quantities in the legendary Beetle

1959

27th November

-

Transition to large scale production

After the Saarland region, having been annexed, is reintegrated into the Federal Republic of Germany, the company quickly manages the transition to large scale production and to find new clients in the automotive industry.

Zinc die casting, machining and chrome-plating with this high level of precision and quality are absolutely a unique selling proposition for VOIT. In mid-November 1959, this entices the first automotive customer to the Saar region who is still operating there today: Bosch Bühlertal

1959

-

Start of zinc die casting production with own galvanization

Products: the first cigarette lighter with a transparent tank and electrical ignition mechanism and mechanical ashtray mainly for customers in France and the Saarland region

1956

-

First composite tools rationalise manufacturing.

1950

-

Birth of the company WILLY VOIT

Equipped with ideas, entrepreneurial spirit and home-made spindle presses, Willy Voit starts up his stamping and embossing workshop in his father-in-law’s forge. He produces typical, small post-war items such as shoe irons, fuel tank caps, accessories for file folders and savings boxes.

From the very beginning, Willy Voit focuses on a cost-effective and rational way of working as well as on large volumes.

20.10.1947