Forming Technologies

Stamping, drawing and roll-bending technology

Plant 1, the headquarters in St. Ingbert, is the location of the competence center for forming technology. It is our most modern manufacturing location for stamping, drawing and roll-bending technology. What is tried and tested here and optimized with regard to the process, is transferred as the standard to all other manufacturing locations. This also applies to aluminium die casting. The VOIT corporate group applies various technologies for cold forming of steel, high grade steel and aluminium at three sites: Plants 1 and 2 of VOIT Automotive in St. Ingbert. With regard to manpower and press forces, the latter plant is the largest in the field of cold forming in the VOIT corporate group.

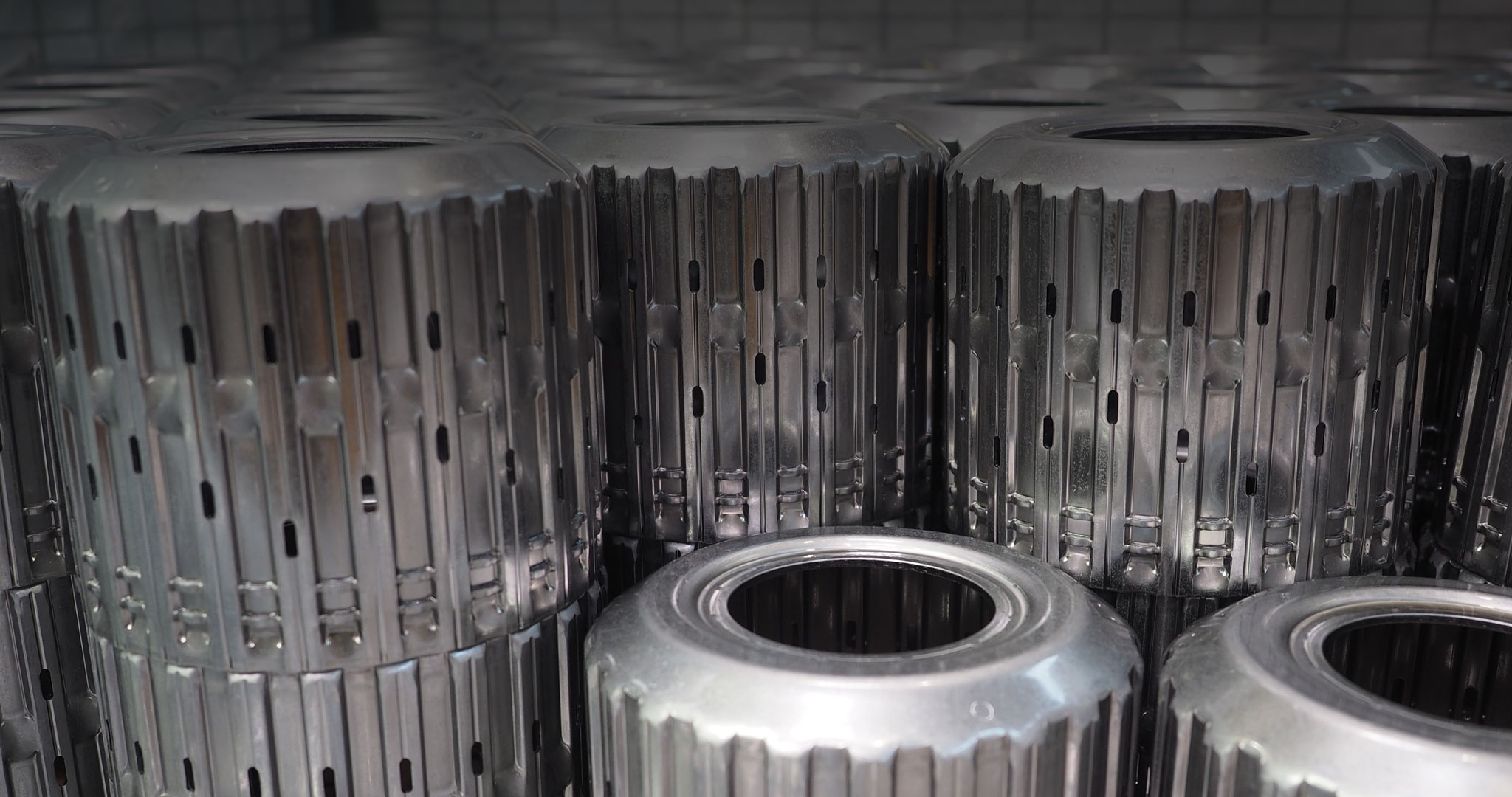

The portfolio is focused on components for drive technology. On large AIDA presses with a pressing force of 1,900 tonnes and 12 individually controllable forming steps, complex drive and clutch components are manufactured to the highest component tolerance in a single production step e.g. internal transmission components such as disk carriers with high degrees of deformation, disk engaging mechanisms with strong teeth and webs/planetary supports with a material thickness of up to 8 mm. The systems are fully interlinked with washing and slide-grinding machines.

On further stamping machines, transfer and deep-drawing presses with tonnages of up to approx. 630 tonnes, steel plates of thicknesses between 0.8 mm and approx. 4 mm are processed in various grades right up to high grade steel to create complex plate structures such as rolled/drawn structures for different electromotor drives.

Also at the St. Ingbert location, VOIT Automotive manufactures highly complex and precise deep drawn parts for use in state-of-the-art automatic transmissions. For this purpose, there are deep drawing presses with a pressing force of 2,400 tonnes including integrated precision cutting lines on which material thicknesses of up to 8 mm are processed. Downstream processes are carried out by interlinked slide grinding and cleaning facilities as well as in joining and assembly work. All components and component groups which leave our premises are delivered ready-to-install and just in time.

The manufacturing departments at all locations of the VOIT corporate group are supported by our Competence Center Tool Construction in St. Ingbert which carries out all services from development, design and simulation to construction, care and optimisation of the tools and prototype construction.